call us +48 732 690 090 or write zamowienia@solmix.pl

Planning to buy a photovoltaic system? One of the most important decisions is the choice of photovoltaic modules. What type of photovoltaic panels is best? How are polycrystalline panels constructed? Why do monocrystalline modules have high efficiency? Which photovoltaic panels to choose? We explain the most important information about modules in a PV system.

More and more households in Poland decide to invest in photovoltaic system. This is not only a way to avoid high electricity price increases, but also to reduce heating costs. In combination with a heat pump, an electric boiler or modern heating panels, photovoltaics can significantly reduce heating expenses, even in comparison with a coal boiler.

Good quality photovoltaic modules are a prerequisite for high power yields and trouble-free operation. To a large extent, it depends on the panels how much electricity can be produced from the sun. On the other hand, photovoltaic panels have to be reliable – any downtime in power production is a loss of valuable kilowatts. Although the construction of photovoltaic panels is not complicated, their quality is of great importance. It is also worth noting that even the best photovoltaic panels will not work properly if they are incorrectly installed. For the installation of PV systems, choose only experienced installers

Photovoltaic panels are divided into polycrystalline and monocrystalline ones. Polycrystalline cells are distinguished by their blue, shimmering colour. The modules are made of non-uniform silicon crystals and their efficiency is about 14-18%. Due to the simplicity of production this type of panels is cheaper than mono-crystalline constructions. In addition to the lower price, the advantages include good operation in poorly insolated places.

Monocrystalline cells are currently the most popular. You can recognise them by their black colour and white dots. They are produced from a single alloy of silicon sand and boron, so they absorb photons better. This manifests itself in higher efficiency of about 16-23%. This obviously comes at a slightly higher price, but it is worth remembering that this is an investment for 25 years or more. There are also monocrystalline panels available on the market which are completely black, so called full black, without white dots. This is purely aesthetic and does not improve performance. However, the elegant and minimalist look of full black panels perfectly suits modern houses, which is why more and more investors choose them. As a matter of interest, amorphous panels, also called non-crystalline, are worth mentioning. It is a technology allowing to produce very thin and even flexible modules. A layer of silicon is applied to another surface, e.g. glass, which makes it possible to obtain aesthetic and minimalist PV panels. The disadvantages of this solution are low efficiency (ca. 6-10%) and lifetime – ca. 10 years.

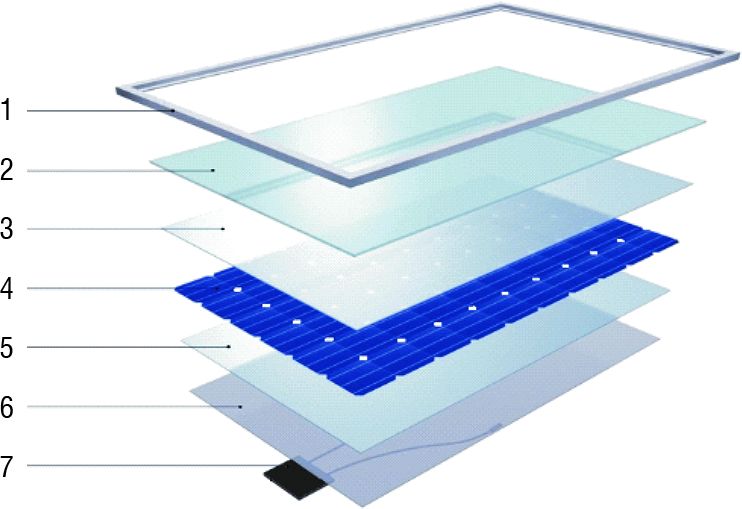

The material responsible for absorbing photons is silicon. In monocrystalline panels it is in the form of uniform wafers. The cells connected in series or parallel are hermetically sealed with EVA (ethylene vinyl acetate) film and covered with tempered glass. This has a high light transmission rate, so that it does not restrict the solar radiation reaching the semiconductor material. On the other side, the photovoltaic panels are protected with an electro-insulating film, usually in white, transparent or black. In recent years, the film is often replaced by glass. When glass-glass modules and bifacial cells are used, double-sided panels can be obtained, absorbing solar energy from both sides. The outer frame of the panels consists of aluminium mounting strips.

Mono-crystalline cells are distinguished by the most advanced technology which guarantees the best use of the photons falling on them. Black monocrystalline panels effectively absorb photons, causing electrons to burst and flow between the negative and positive electrodes. In this way, direct current is produced, which is then changed in the inverter to alternating current, which is the one available in the socket.

The efficiency of monocrystalline panels is mainly due to the very smooth, uniform surface of the cells, which absorbs solar radiation most effectively. A uniform plate of silicon performs better than a non-uniform layer of compressed crystals. It provides greater freedom of movement of electrons, which affects the efficiency of the cell. However, in order to create it, a cylindrical single crystal of silicon is first cast using the Czochralski method. It is formed slowly, over a period of 48 hours, by dropping a crystal embryo, i.e. a single block of silicon, into a uniform mass. The cylindrical crystal is then cut into round slices from which nearly square cells are cut to save space.

Blue polycrystalline panels are made from many silicon crystals, so the surface is not as uniform. Within the edges of the cells, single crystals can be seen. This is a remnant of the crystallization of many blocks of silicon into one large block. The silicon is melted at 1500 degrees Celsius and then an anti-reflective coating is applied to give the cells a blue colour.

Their principle of operation and construction is almost identical, therefore they have a similar durability and resistance to weather conditions as monocrystalline cells. Due to the fact that the cells are not made of a single block of silicon, polycrystalline cells are however slightly more prone to micro-cracks, which reduce efficiency.

The choice between monocrystalline and polycrystalline panels is not as obvious as it might seem. While installers encourage the more efficient and durable monocrystalline panels, don’t rule out polycrystalline cells. They are lower in price and can therefore provide a quicker return on investment. The condition, however, is that they require slightly more space on the roof or ground to achieve the same power. Lower efficiency of the panels is compensated by their surface area. Polycrystalline panels with a similar surface area have a significantly lower peak power output. However, if you have a large roof area or can afford a large ground installation, the choice of polycrystalline cells does not have to be inferior.

In practice, however, the vast majority of investors (even 98%) choose monocrystalline panels. The reason is not only greater efficiency, but also aesthetics. The deep black of monocrystalline panels blends in much better with modern and classical buildings than the blue colour. In addition, the space-saving design makes it easier to expand the photovoltaic system in the future, for example to power a heat pump. Better efficiency, a more favourable temperature coefficient, lower installation costs and a more aesthetic appearance clearly speak in favour of monocrystalline panels.

Want to know more? Check out our PV Panel Ranking 2021/2022

Our offer

Useful

Shop